TMR-24 Contract Development Of Electronics

We help companies improve their products by making them more technologically advanced and increasing their value in the eyes of customers. This allows you to gain competitive advantages by creating added value.

Our core competencies are the development of electronic devices for industry, retail, the Internet of Things and other industries.

We carry out a full cycle of work from the elaboration of ideas and concepts to prototyping and preparation for mass production.

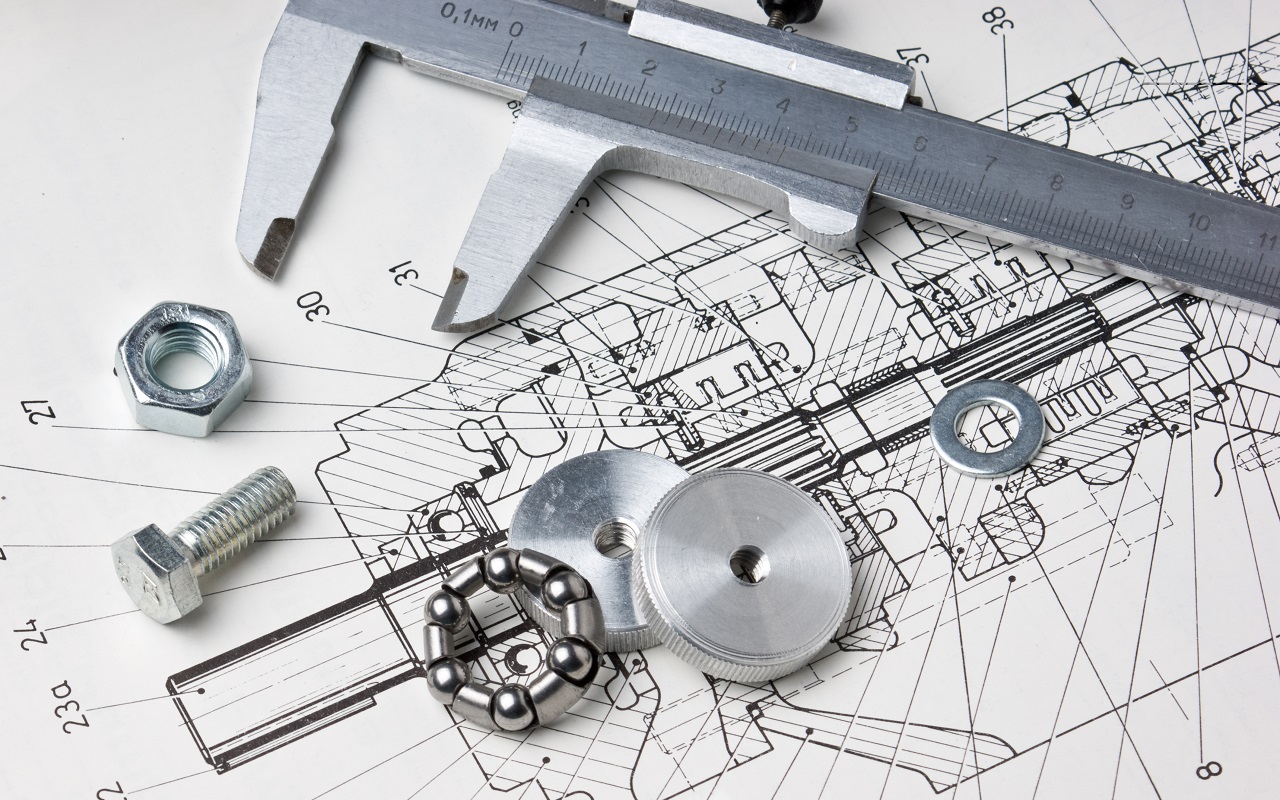

Definition of requirements, goals and development of technical solutions.

The first step in the contract development of industrial electronics is to define the requirements and objectives of the project. Next, the process of developing technical solutions takes place. This stage includes the selection and evaluation of available components, as well as the development of a prototype system.

Prototyping and preparation for mass production.

When the development is completed and all the requirements and goals of the project are met, the product is produced. At this stage, the production of product prototypes, testing and correction of defects found, the production of the first serial batches with the development of technology takes place.

Technical documentation and certification of the developed products.

The documentation must be prepared in accordance with the applicable standards and regulations. Certification confirms that the product meets all requirements and regulations, as well as performs the functions for which it was intended.

Definition of requirements, goals and development of technical solutions.

When designing large and complex systems, problems arise not only with the properties of their component parts – elements and subsystems, but also with the laws of the functioning of the object as a whole, considered as system-wide problems.

The consequence of this is the need to solve a wide range of specific tasks, which include: determining the overall structure of the system and requirements for elements and subsystems, organizing interaction between them, choosing optimal modes of operation, optimal control of processes occurring in the system, taking into account the influence of the external environment, etc.

Designing complex systems usually involves two stages:

-

Macro-design or external design, in the process of which structural and functional tasks are solved as a whole.

-

Micro-design or internal design related to the development of system elements as physical units of equipment.

In accordance with the terms of reference, one or more detailed studies can be determined. The simulation results allow us to determine the 8 values of the systems performance indicators, justify its optimal structure and make recommendations for improving the options under study.

Mathematical modeling is a powerful and effective tool for the study of complex objects, systems and processes in various fields. The variety of processes occurring in the systems and objects under study also determines the variety of mathematical methods and tools used in the design process.

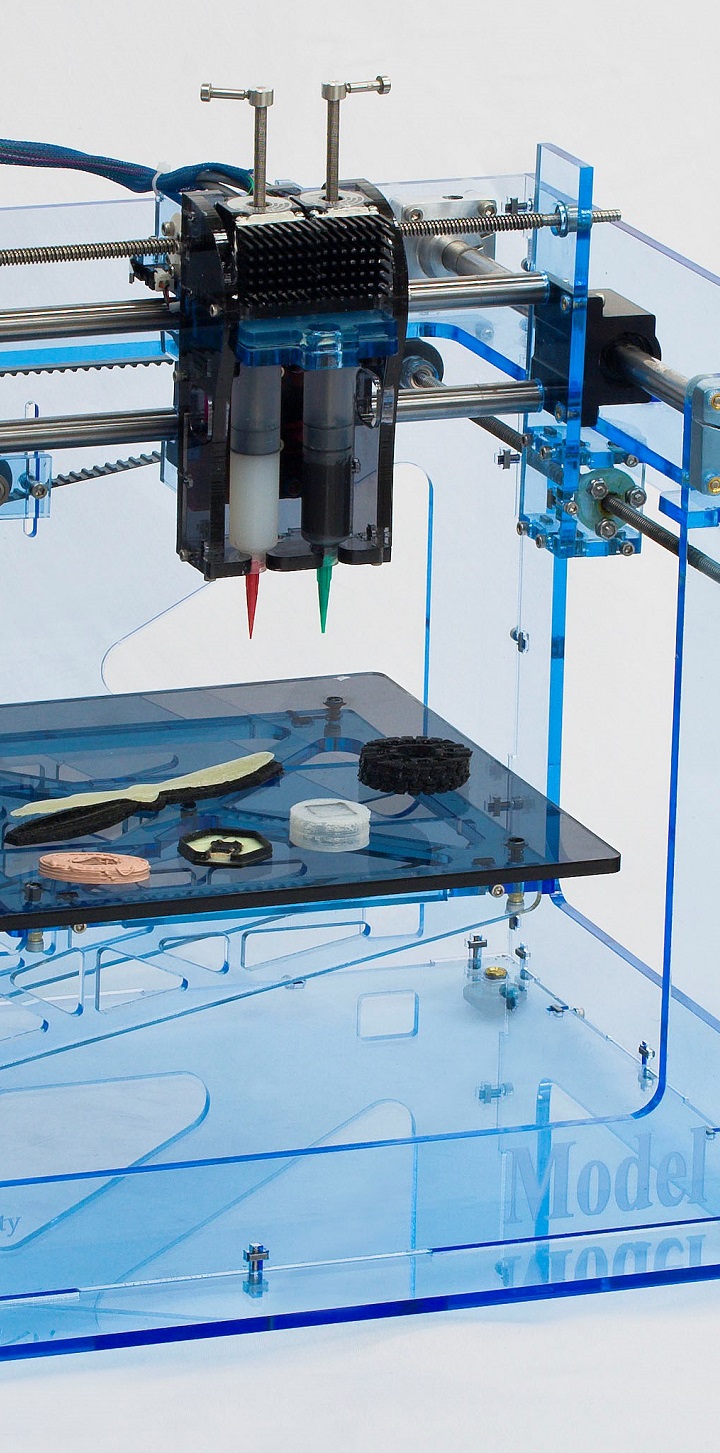

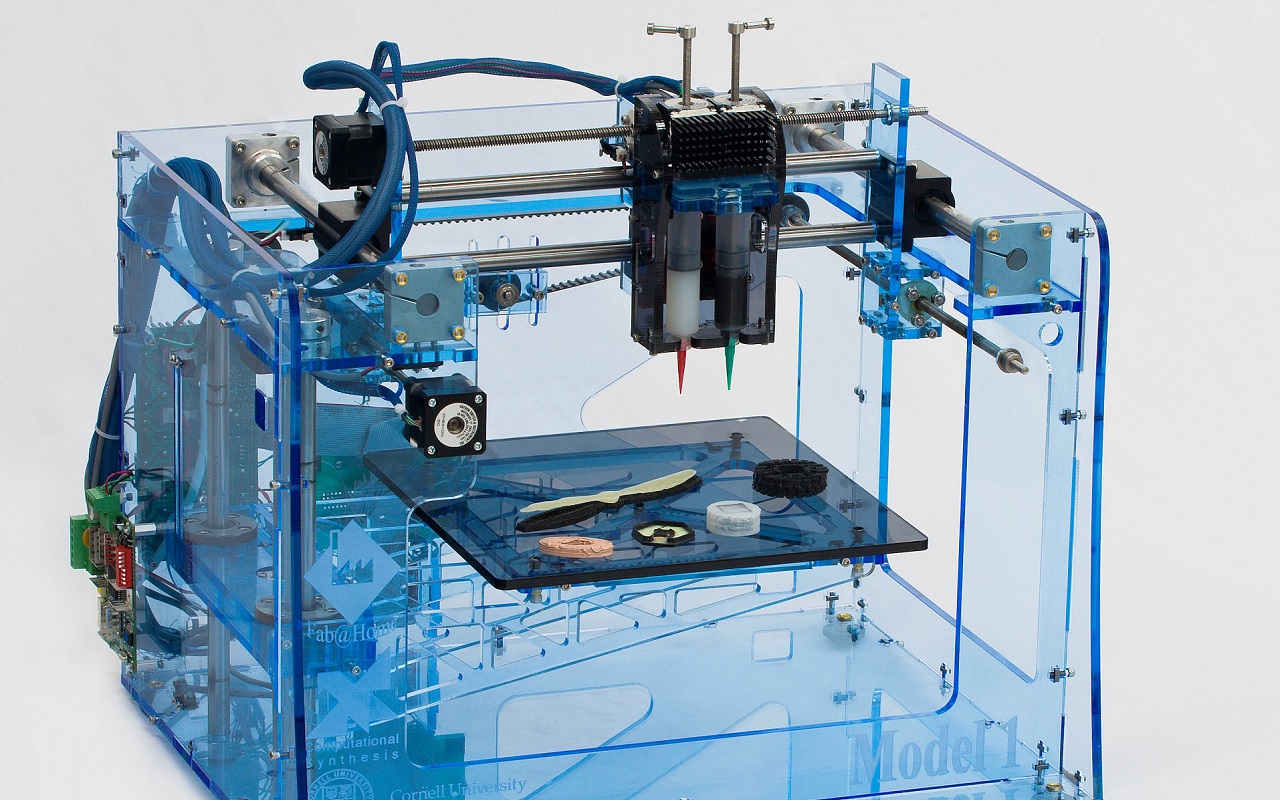

Prototyping and preparation for mass production.

Physical models allow designers to share their concepts with colleagues, clients and employees using means that are not comparable to the usual visual representation of the design on the screen. Rapid prototyping promotes clear and effective communication with users, thanks to which creators can better understand their needs, and then refine and improve products.

Detecting and eliminating design flaws at the early stages of design and production will help companies avoid costly redesign and the use of additional tools. Rapid prototyping allows you to thoroughly test prototypes that look and work like finished products before starting production and reduce the risks associated with operational suitability and complexity of production processes.

Evaluation criteria for rapid prototyping:

-

Permission.

-

Accuracy.

-

Surface quality.

-

Ease of use.

-

Materials.

-

Methods of application.

-

Price range.

From the point of view of ESTPP, technological preparation of production provides for the solution of tasks in the following areas: ensuring the manufacturability of the product design; design of technological processes and development of technological documentation; design and manufacture of technological equipment; organization and management of the process of technological preparation of production.

The designed technological process, the choice of equipment and its operating modes determine the basic norms for the consumption of working time, raw materials, materials, fuel, energy and other elements of production per unit of production.

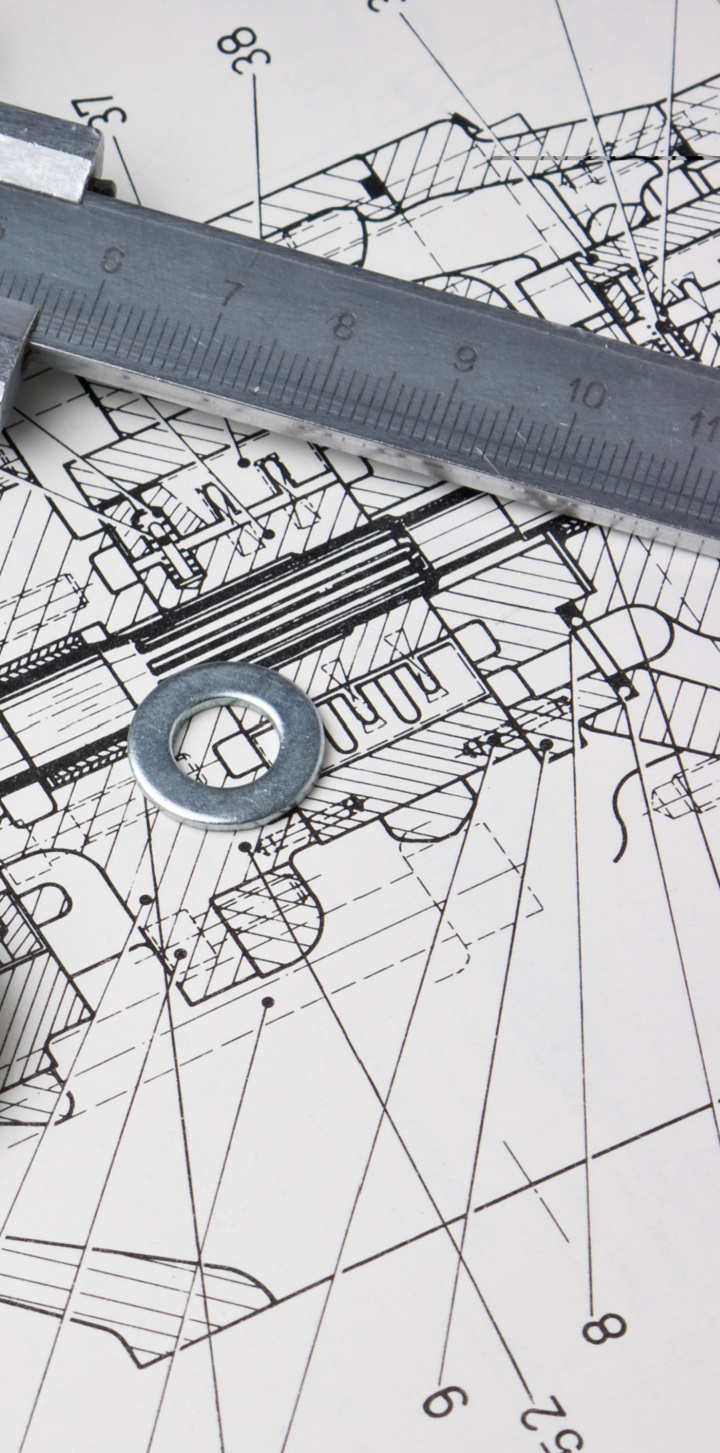

Technical documentation and certification of the developed products.

The Unified System of Technological Documentation (ESTD) is a set of interstate standards and recommendations that establish interrelated rules and regulations on the procedure for developing, completing, processing and handling technological documentation used in the manufacture, control, acceptance and repair (modernization) of products (including collection and delivery of technological waste).

The main technological documents are used, as a rule, in the workplace. Auxiliary technological documents are developed in order to improve and optimize the organization of work on technological preparation of production. Derived technological documents are used to solve problems related to the rationing of labor costs, the issuance and delivery of materials, semi-finished products and components.

The main technological documents contain various information:

-

Development of design documentation.

-

Development of technical documentation.

-

Design of equipment and tooling.

-

Development of the product passport and operating instructions.

-

Preparation of documentation for certification.

Quality control is a constant activity to obtain information about the signs, parameters and characteristics of products, compare the results obtained with the established requirements and identify inconsistencies.

The overall goal of certification is to give confidence to all interested parties that products, processes and services meet the established requirements.